Microstructural Analysis

Nanolytical specialises in microstructural and crystallographic analysis utilising a range of microscopy techniques and X-ray diffraction analysis to analyse samples to <5nm. We offer quantitative elemental and phase analysis, grain size analysis and volume fraction analysis in addition to imaging.

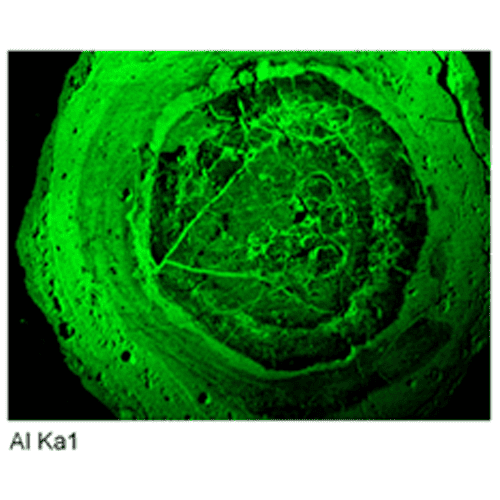

Scanning Electron Microscopy (SEM)

Nanolytical offers a full suite of SEM techniques, data collection and interpretation, and microstructure to macro-structure correlation analysis.

In addition to high resolution SEM imaging to <5nm, we also offer Energy Dispersive Spectroscopy (EDS), backscatter imaging (compositional variation), high resolution elemental mapping, together with qualitative as well as quantitative data analysis.

We have many years of experience in best sample preparation techniques for all measurements to collect optimal results with error minimisation, and also offer sample mounting, grinding and polishing services.

Transmission Electron Microscopy (TEM)

Nanolytical offers expertise in a full suite of TEM techniques, sample preparation and data analysis.TEM is widely used in nano-particle characterisation, and offers resolution to 1 nm scale.

Optical Microscopy

Nanolytical offers optical microscopy analysis. Most samples for optical microscopy require resin mounting and polishing. Our people have considerable experience with polishing a wide range of sample types across metals, ceramics and cermet composites.

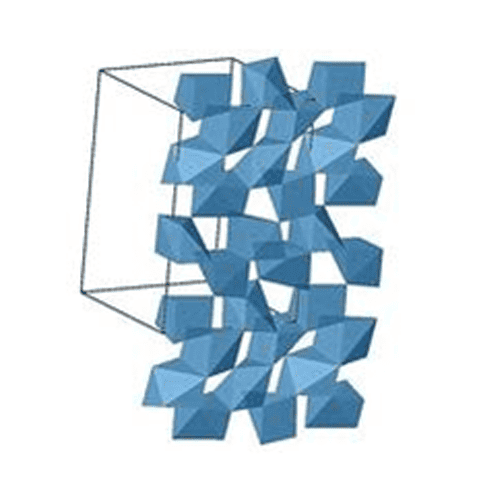

X-Ray Powder diffraction (XRD)

Nanolytical provide a range of XRD services from basic diffraction data collection for in-house analysis, to quantitative phase analysis and full Rietveld refinement. We have a wide range of experience in phase identification and quantification, across a range of industries which include wear ceramics, metals, raw mining ores, flotation concentrates and tailings samples, synthetic minerals, industrial inorganics and slurries.

A wide range of X-ray diffraction services include:

• phase identification• semi-quantitative and quantitative analysis

• Rietveld refinement

• crystallite size determination

• high temperature XRD

• Lattice parameters refinement

• Reflection and transmission mode geometries

Qualitative Powder XRD

Identification of major and minor phases using a number of crystallographic databases to search match all known phases.

Quantitative and Semi-Quantitative Powder XRD

Semi-quantitative XRD refinement is commonly carried out on samples with unknown phases or unknown structures, and can have accuracy to ~1%.

Quantitative powder XRD utilises an internal standard for phase concentration analysis, and typically has higher accuracy than semi-quantitative analysis.

In combination with X-Ray Fluorescence (XRF) analysis, quantitative X-ray Diffraction is the state of the art tool for determining chemical composition and phase distribution.

Lattice parameters refinement

Lattice parameter refinement is useful in determining compositional variation in solid solutions, giving the degree of elemental substitution, and can be used to determine. Many phases in industry and geochemistry are cationic substituted solid solutions with variable compositions. The XRD finger print pattern will look identical between these phases, however, unit cell refinement will distinguish between similar materials or similar phases in the solid solution series.

Carrying out XRD analysis as a function of temperature combined with lattice refinement allows the most accurate determination of the thermal expansion coefficient.

Synchrotron Facilities

Australian Synchrotron Facility in Melbourne is a world class facility that allows specialist XRD work. Our people have many years experience in using Powder Diffraction beam line, experiment design, data collection and data analysis. We can assist you with experiment design and will travel on your behalf for data collection to Melbourne as well as assist you with post collection analysis.